| University | Singapore Management University (SMU) |

| Subject | Mechanical Engineering |

Background

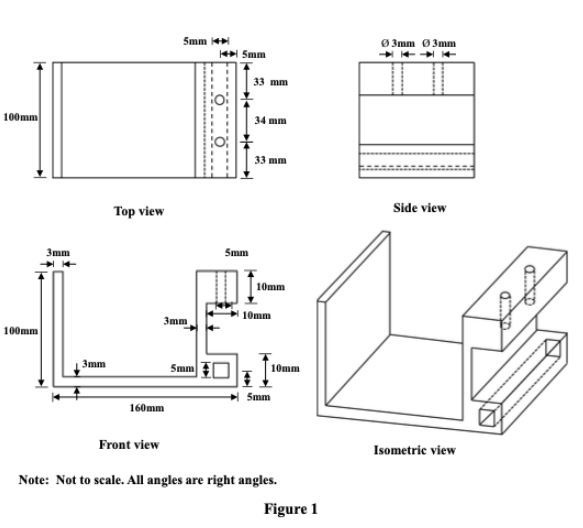

As an element of an assembly, the component shown in Figure 1 has been designed by a junior designer. The two 3 mm diameter holes are a key feature for the anchoring of the component to the assembly. The 5mm square through-hole is for wiring concealment for the aesthetic purpose; provided that it is attached to the external surface of this U-element, its exact location is of no consequence.

The service temperature range of the component is from room temperature to 80°C, and the component has to be impact resistant. To satisfy also other considerations, such as strength, stiffness, weight, and production cost, the designer has chosen Polymethyl Methacrylate (PMMA) as the material for the component.

Prototypes of the assembly are to be tested before mass production. For prototype testing, 20 units of this component are to be produced initially. However, it is expected that to satisfy initial demand, 500,000 units of the component are required, and possibly more if there is a great demand for the assembly.

Buy Custom Answer of This Assessment & Raise Your Grades

The disagreements

The production engineer refuses to produce the 20 units of PMMA components as requested by the designer. His comments are:

- Even for prototyping purposes, the 20 units of PMMA components as designed cannot be made and the design must be revised. In addition, for cost and speed of fabrication, instead of PMMA, the raw material should be replaced by aluminum sheet, with sheet metal bending and machining as the manufacturing processes.

- In any case, for the mass production of the 500,000 units of PMMA component, a suitable manufacturing process is plastic injection moulding. However, the component as designed cannot be manufactured by plastic injection moulding and the design has not been optimised to lower the complexity and cost of production.

Solution required

As you are in charge of both the design and production departments, this disagreement is brought to your attention. To resolve the various issues, please provide solutions and suggestions with justifications, and to state any assumptions made, In particular, do address explicitly the followings, but not limited to them:

- The design, taking into consideration the functional requirements and manufacturing processes.

- The choice of materials, for both prototyping and mass production.

- The choice of manufacturing processes, for both prototyping and mass production.

Do state any necessary assumptions required, including the possibility of revising some dimensions and features of the design for manufacturing (i.e. assuming that some design parameters can still be revised).

Do provide appropriate headings to facilitate ease of reading. Present your solutions precisely (e.g. in point form), and with appropriate illustrations.

All our engineering assignment writers are highly qualified and experienced in serving top-quality assignments and essay writing services to students all around the world. You can completely trust us and have your mechanical engineering assignment writing needs covered with perfection.

Looking for Plagiarism free Answers for your college/ university Assignments.

- HRM331: Talent Management – Strategic Shift from the War for Talent to the Wealth of Talent

- Marginalised Populations – The Structural and Cultural Exclusion of People Experiencing Homelessness in Singapore

- CVEN3501 Assignment 2: Groundwater Modelling of Drawdown from a Pumping Bore

- CSCI312 Assignment 2: Conceptual Modelling and Implementation of a Data Warehouse and Hive Queries

- CH2123 Assignnment : Fugacity, VLE Modeling & Henry’s Law Applications

- BAFI1045 Assignment -Constructing and Evaluating Passive and Active Portfolios Based on the Straits Times Index (STI)

- PSB501EN Assignment 1: Engineering Systems Integration: A Multi-Technique Approach to Mechanical Analysis

- FIN2210E/FIN2212E Group Assignment: Financial Risk Management Analysis of Bursa Malaysia Companies

- FLM101 Assignment: A Cinematic Dissection: Stylistic Elements and Their Thematic Significance

- Assignment: Transforming Talent in the AI Era: From War to Wealth through Ecosystem Innovation