| University | Coventry University (CU) |

| Subject | 207MAE :THERMOFLUID MECHANICS |

This laboratory exercise is to construct the vapor-compression refrigeration cycle on the pressure-enthalpy property diagram for a refrigeration cycle demonstration unit and assess its thermal performance, which is the coefficient of performance.

Students will identify the main component of the apparatus (i.4. condenser, evaporator, compressor and throttle expansion valve) and analyze the thermodynamic processes occurring within. Temperatures and pressures of the liquid and gas phases of the refrigerant at various locations (thermodynamic states) will be measured to construct the refrigeration cycle.

Theory for the vapor-compression cycle The vapor-compression cycle is the most commonly used refrigeration cycle and involves the same four processes as a heat engine cycle but in the reverse order (i.e. evaporation 4 compression 4 condensations .4 expansion throttling).

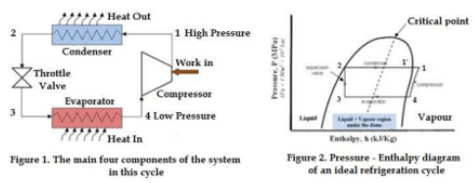

A schematic representation of the main components in this cycle is shown in Figure 1. The corresponding pressure-enthalpy diagram is shown in Fig. 2.

the temperature of the refrigerant increases during this isentropic compression process to well above the temperature of the strumming medium.

The refrigerant then enters the condenser as superheated vapor at the state I and leaves as a saturated liquid at state 2 as a result of heat rejection to the surroundings. The temperature of the refrigerant at this state is still above the temperature of the surroundings.

The saturated liquid refrigerant at state 2 is throttled to the evaporator pressure by passing it through an expansion valve or capillary tube. The temperature of the refrigerant drops below the temperature of the refrigerated space during this process. At the same time, the pressure is greatly reduced.

The refrigerant enters the evaporator at state 3 as a low-quality saturated mixture, and it completely evaporates by absorbing heat from the refrigerated space.

The refrigerant leaves the evaporator as saturated vapor (state 4) and re-enters the compressor, completing the cycle.

Procedure

The lab engineer will provide a briefing of the equipment before conducting the experiment.

identify cycle components, locate the transducers, selector switches of throttle type, and sub-cool setting.

2. Set pre-determined temperature setting, throttle type and sub-cool setting (on oft).

3. Turn on the main switch and the compressor will start. Nonce the Fan Coil unit will turn on automatically.

4. Allow the unit to rim for at least 15 – 20 minutes to reach approximate thermal equilibrium before any measurement is recorded. The time taken to stabilise will depend upon the local ambient conditions.

5. Record the temperature and pressure readings, as shown in Table 2. Three different sets of readings are to be collected.

Analysis and Report Writing

For each set of data,

I) sketch the refrigeration cycle on the R22 p-h diagram (o.a. from f3 or 4] in appendix) by marking the refrigerant temperatures recorded,

2) calculate an ideal reversed Carrot Refrigeration Cycle working between the same condenser and evaporator temperatures of the refrigeration cycle, 3) calculate the q, and /I of the compressor based on the cycle.

Hire a Professional Essay & Assignment Writer for completing your Academic Assessments

Native Singapore Writers Team

- 100% Plagiarism-Free Essay

- Highest Satisfaction Rate

- Free Revision

- On-Time Delivery

If you are looking for do my assignment for me then you should take help from our experts who have years of experience in making perfect quality solution on engineering assignments at an affordable cost.

Looking for Plagiarism free Answers for your college/ university Assignments.

- HRM331: Talent Management – Strategic Shift from the War for Talent to the Wealth of Talent

- Marginalised Populations – The Structural and Cultural Exclusion of People Experiencing Homelessness in Singapore

- CVEN3501 Assignment 2: Groundwater Modelling of Drawdown from a Pumping Bore

- CSCI312 Assignment 2: Conceptual Modelling and Implementation of a Data Warehouse and Hive Queries

- CH2123 Assignnment : Fugacity, VLE Modeling & Henry’s Law Applications

- BAFI1045 Assignment -Constructing and Evaluating Passive and Active Portfolios Based on the Straits Times Index (STI)

- PSB501EN Assignment 1: Engineering Systems Integration: A Multi-Technique Approach to Mechanical Analysis

- FIN2210E/FIN2212E Group Assignment: Financial Risk Management Analysis of Bursa Malaysia Companies

- FLM101 Assignment: A Cinematic Dissection: Stylistic Elements and Their Thematic Significance

- Assignment: Transforming Talent in the AI Era: From War to Wealth through Ecosystem Innovation